¿Por qué el acabado de la superficie es fundamental para el rendimiento del sello de polímero?

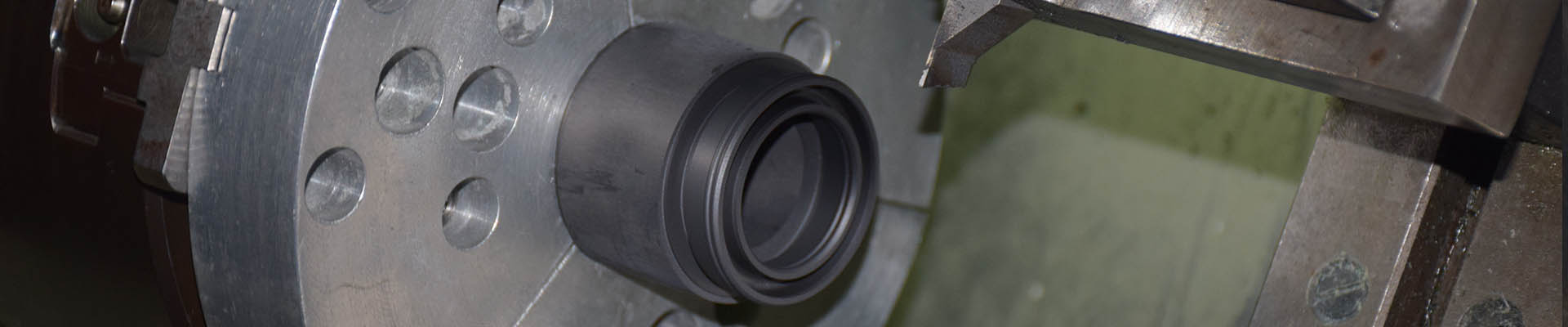

El acabado de la superficie es un factor crítico en sello de polímero El rendimiento es importante porque afecta directamente la eficacia del sellado, la fricción y la durabilidad. A diferencia de los elastómeros más blandos, que se adaptan a superficies rugosas, la mayoría de los materiales poliméricos son más duros y requieren texturas superficiales específicas para crear un sellado fiable y duradero.

Razones clave por las que el acabado de la superficie es importante:

Parámetros clave a considerar

Si bien la rugosidad promedio (Ra) es una métrica común, no refleja la situación completa. Otros parámetros críticos incluyen:

Rz: Profundidad media de rugosidad, que se centra en la diferencia de altura promedio entre los picos más altos y los valles más bajos.

Disposición: Dirección del patrón superficial dominante (p. ej., lineal o reticulado). Un acabado con una disposición lineal paralela a la dirección del movimiento en una aplicación reciprocante tiene mayor probabilidad de generar fugas que un patrón reticulado.

Dureza: La dureza de la superficie de contacto también es un factor importante. Generalmente se recomienda una superficie dura (p. ej., de 40 a 60 Rockwell C) para evitar que el sello dañe el hardware, pero esto hace que la calidad inicial del acabado superficial sea aún más crítica.

En última instancia, el acabado superficial ideal para una aplicación de sello de polímero es un rango específico que debe seleccionarse cuidadosamente en función del material del sello (por ejemplo, PTFE frente a elastómero), si la aplicación es estática o dinámica y el tipo de medio que se va a sellar (gas, líquido, etc.).

Recomendaciones generales de acabado de superficies

|

Aplicación / Material |

Rango Ra típico recomendado |

|

Sellos de elastómero (caucho) |

|

|

Sellos de polímero (PTFE, etc.) |

|

|

Gases de sellado / Criogenia |

Muy bien, tan bajo como

|

|

Generalmente puede tolerar un acabado ligeramente más rugoso que sellos dinámicos |

En resumen, seleccionar el acabado superficial correcto es una consideración de ingeniería vital. No se trata solo de que la pieza luzca atractiva, sino de proporcionar el entorno microscópico preciso necesario para que el sello de polímero alcance su máximo rendimiento operativo y longevidad.

Nuevo blog

© Derechos de autor: 2026 Guangzhou JST Seals Technology Co., Ltd. Reservados todos los derechos.

Escanear a WeChat