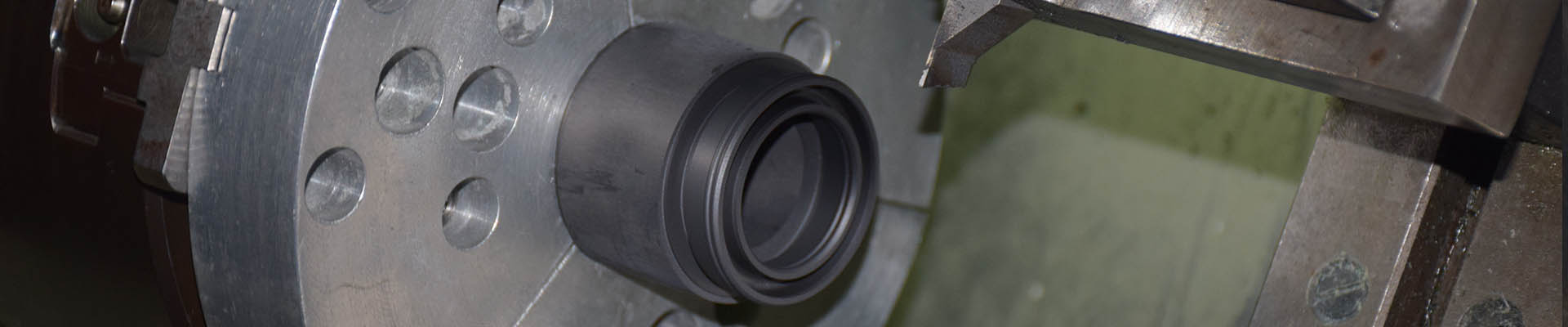

JST Seals: Capacidades de prueba PR2 internas para soluciones de sellado avanzadas

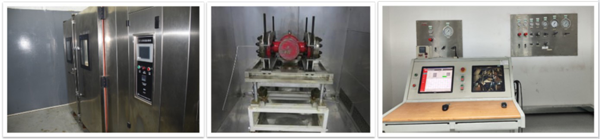

Sellos JST Contamos con amplias capacidades internas para realizar pruebas PR2 en condiciones rigurosas, lo que garantiza la fiabilidad y el rendimiento de nuestros productos de sellado. Nuestras instalaciones están equipadas con equipos de prueba avanzados, incluyendo comprobadores de abrasión de materiales, sistemas de prueba PR2/PR2F de alta y baja temperatura, equipos de temperatura ultrabaja que utilizan nitrógeno líquido (-320,8 °F / -196 °C) y una gama de herramientas de simulación personalizadas diseñadas para replicar entornos operativos reales.

Realizamos pruebas de acuerdo con los estándares de la industria y también podemos desarrollar programas de pruebas a medida según los requisitos específicos del cliente. Nuestros equipos son compatibles con:

⚫ Presión de prueba: Líquido: 0–50 000 psi │ Gas: 0–25 000 psi

⚫ Rango de temperatura: -94 °F a 482 °F (-70 °C a 250 °C)

⚫ Medios de prueba: agua, petróleo, gas

⚫ Rango de tamaño: 2 a 9 pulgadas

El sistema configurado permite el monitoreo y la retroalimentación en tiempo real de los movimientos del actuador, simulando el funcionamiento real del dispositivo para una evaluación precisa del desempeño.

JST Seals ha realizado con éxito numerosas pruebas de validación para aplicaciones críticas, entre las que se incluyen:

⚫ Pruebas PR2/PR2F para empaquetadura del vástago de la válvula de compuerta

Además, JST cuenta con capacidades de pruebas criogénicas de hasta -196 °C (-321 °F) con nitrógeno líquido. Hemos realizado con éxito pruebas a temperaturas ultrabaja en sellos activados por resorte (por ejemplo, material TFM con resortes de aleación chapados en oro) en condiciones extremas, demostrando un rendimiento confiable incluso a -196 °C.

En JST, nos aseguramos de que cada sello cumpla con los más altos estándares de calidad y durabilidad, validados a través de pruebas precisas y orientadas al cliente.

Nuevo blog

© Derechos de autor: 2026 Guangzhou JST Seals Technology Co., Ltd. Reservados todos los derechos.

Escanear a WeChat