Sellos criogénicos para operaciones de GNL: Superando condiciones extremas con soluciones energizadas por resorte

En las operaciones de gas natural licuado (GNL), las válvulas y los equipos se enfrentan a algunas de las condiciones más adversas del planeta: temperaturas inferiores a -196 °C (-320 °F), presiones superiores a 750 psi y ciclos térmicos constantes que provocan la expansión y contracción de los componentes y la tensión del material. Estos desafíos exigen sellos que mantengan su integridad a largo plazo y garanticen un funcionamiento seguro y sin fugas.

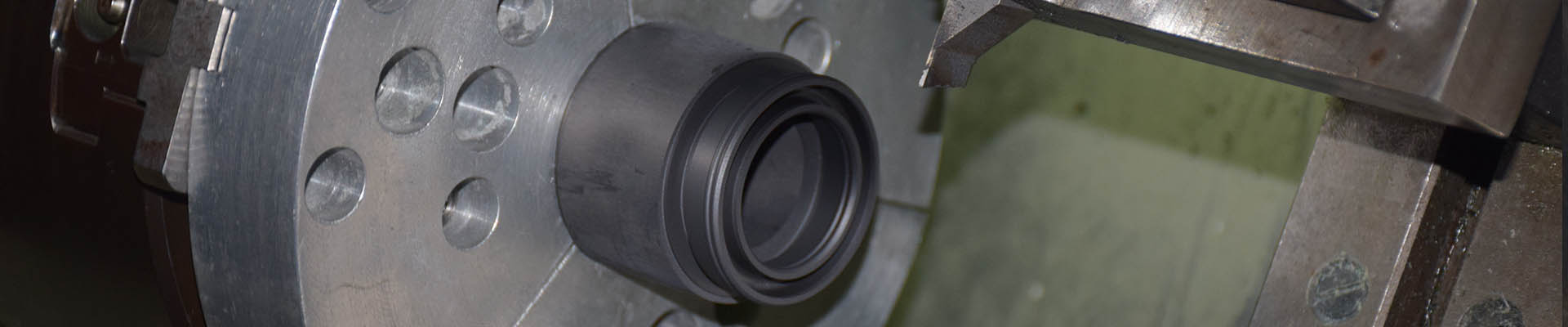

Efficient, reliable valve performance is critical to the success of any LNG/CNG operation, and seals play a central role in keeping valves up and running. But their job is made difficult by the demanding service conditions.

Challenges in LNG Valve Sealing

LNG operations subject seals to unique stresses:

Spring-energized seals are vital across LNG infrastructure, including:

With the right material formulation and design, they can actually provide much better sealing service than alternative technologies, such as metallic seals, elastomeric seals and packings—especially in dynamic applications. In fact, the right polymer seals can actually help engineers achieve new levels of valve performance.

Sealing at cryogenic temperatures has its own unique set of challenges. JST has a wide range of solutions for cryogenic sealing applications. Cryogenic seals require skillful design by combining the right type of material, seal configuration, and spring energizer to overcome the dimensional fluctuation of all mating parts.

Upgrade your LNG systems with JST’s cryogenic sealing solutions —engineered to keep your operations running smoothly, safely, and leak-free.

Nuevo blog

© Derechos de autor: 2026 Guangzhou JST Seals Technology Co., Ltd. Reservados todos los derechos.

Escanear a WeChat