Elegir sellos para una válvula criogénica

Elegir el sello adecuado para válvulas criogénicas es fundamental para garantizar un rendimiento confiable en entornos de temperatura extremadamente baja. Aquí hay una guía detallada para ayudarlo a tomar una decisión informada:

Factores clave a considerar:

1: Rango de temperatura de funcionamiento

Las válvulas criogénicas normalmente funcionan a temperaturas tan bajas como -196 °C (-320 °F) para nitrógeno líquido o incluso inferiores para helio líquido. Asegúrese de que el material del sello mantenga su integridad y flexibilidad a estas temperaturas.

2: Compatibilidad química

El material del sello debe resistir la degradación de los medios, como gas natural licuado (GNL), oxígeno, nitrógeno, helio o hidrógeno.

3: Tipo de sello

Elija entre sellos dinámicos (para piezas móviles) y estáticos según la aplicación. Los sellos dinámicos requieren mayor flexibilidad y resistencia al desgaste.

4: Clasificaciones de presión

Los sellos deben soportar las presiones operativas manteniendo un sello hermético.

5: Normas reglamentarias y de seguridad

Asegúrese de que los sellos cumplan con los estándares relevantes, como ISO, ASME o certificaciones específicas para el servicio de oxígeno.

6: Ubicación del sello

Diferentes ubicaciones utilizarán diferentes diseños de sellos.

Materiales recomendados:

1: PTFE (politetrafluoroetileno)

Ventajas: Excelente resistencia química, baja fricción y estabilidad a temperaturas criogénicas.

Limitaciones: Baja elasticidad, que requiere anillos de respaldo o diseños específicos para mantener la estanqueidad

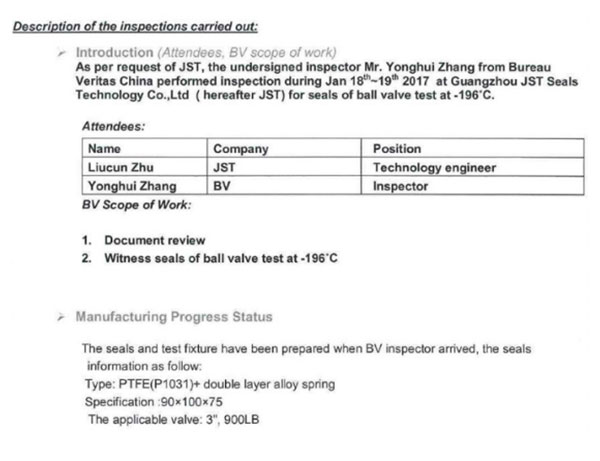

JST tiene una amplia experiencia en el diseño de sellos de válvulas criogénicas.

BV fue testigo de todo el proceso de prueba.

Nuevo blog

© Derechos de autor: 2026 Guangzhou JST Seals Technology Co., Ltd. Reservados todos los derechos.

Escanear a WeChat